Germany based Uhlmann Pac-Systeme and pester pac automation present new end-of-line packaging machines for Uhlmann pharmaceutical packaging lines. “Uhlmann powered by pester pac automation” denotes four new models — a stretch-banding machine, an overwrapper, a case packer, as well as a combined unit integrating a case packer and a palletizing module. The two companies have jointly developed these new end-of-line machines and integrated them into Uhlmann lines, forming holistic solutions that meet current pharmaceutical packaging needs, said Uhlmann.

Uhlmann Pac-Systeme is a global systems supplier for packaging pharmaceutical products in blisters, bottles, and cartons. Uhlmann provides consultation, project management, extensive services, and digital solutions from a single source in addition to its innovative packaging lines. The company is part of the Uhlmann Group and has a presence in India as well. The experts from Uhlmann India offer support concerning the pharmaceutical packaging process in India. As of the beginning of 2016, Uhlmann is represented by its support service and sales company based in the Chakan Industrial Area in the city of Pune in the west of India.

Konstantin Gerbold, global product manager at Uhlmann, said, “Pester is a technological leader specializing in the development and building of end-of-line packaging machines, and in automation solutions. Top companies in the pharmaceutical and consumer industry rely on over 45 years of experience and 8,000 machines installed worldwide. These figures rank Pester among the leading companies in the sector. Offering pharmaceutical safety, compact, GMP-compliant machine design, and reliability, the newly developed ‘Uhlmann powered by pester pac automation’ machines ideally complement our blister and bottle lines. We have been working in close cooperation since December 2019 and are pleased to now present the first results of this partnership — four new types of machine. They can be fully integrated into our lines as they are compatible with our operating system, our design, and our software. The added benefit for our customers is enormous.”

New end-of-line packaging machines for Uhlmann lines

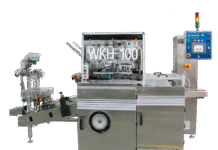

Pharmaceutical companies can now use the new Stretch-banding machine ES 60 as a downstream extension to Uhlmann lines. According to the company, it is suitable for multi-layer bundles at high production speed. Assisted by a positioning device and stacker, cartons can be moved to form various bundle configurations. The tear control function monitors both the top and bottom film to ensure high process reliability, while the film splicer allows an automatic film reel change, so production continues uninterrupted.

Benefits of the ES 60 are the high standard of user-friendliness and its space-saving design. As with all four end-of-line packaging machines, it is easily controlled using the SmartControl operating system integrated into the packaging line. This also assists the user during a format changeover, which can be completed in less than ten minutes as few format parts are involved. The GMP-compliant cantilever design of all the new portfolio machines permits a clear view, good accessibility, and easy cleaning. The integration of extensive protection, monitoring, and early warning features ensures a smooth process.

Uhlmann said, ease of use, transparency, and fast format changeovers are also offered by the EW 60, a machine for the automated full overwrapping of single or multiple bundles in heat-sealable film. Full sealing increases protection because subsequent product tampering is immediately recognized. A servo motor controls the film’s accurate dispensing, and format and film changeovers are quickly completed on account of the small number of plug-in format parts.

The Case packer EC 12 uses the side-loading principle to package cartons or bundles in cases ready for dispatch efficiently. All steps – unfolding of the case blanks, filling, two-sided closure – require minimum space and are incredibly accurate, it said. The infinitely variable format adjustment allows the flexible handling of various case sizes, while the upending and turning station permits optimum use of the case volume. A unique feature is a wide-format range – small to large cartons and cases – all can be handled. The EC 12 can also be optionally fitted with a labeling unit.

Those also requiring a palletizer now have the option of the ECP 12. The company’s innovative, space-saving combination of a case packer and a palletizing module merges two packaging steps into one productive unit – for integrated and automated end-of-line packaging with case handling, labeling, monitoring, and palletizing. This claims to ensure unique product protection. Identification, marking, and inspection systems are integrated into each process step. Two pallet stations mean that a pallet can be replaced during ongoing operation – no line stop is necessary. The entire handling process uses robot technology, resulting in low operating costs and maximum flexibility. Furthermore, the ECP 12 can be fitted with a labeling unit and compatible feeding systems.

“By adding these new packaging machines, we are successfully extending our portfolio. This underlines our proficiency in line architecture and the importance of innovative packaging systems in the field of end-of-line packaging. I am confident that this is just the beginning of a very successful and fruitful cooperation with Pester,” Gerbold stated.