Ever smaller batches for individual therapeutic approaches, new cost-intensive biopharmaceuticals, and the Covid-19 pandemic are changing the pharmaceutical industry more rapidly than ever before. Syntegon Technology showcases solutions to these challenges at the virtual Achema Pulse from 15 to June 2021. “Highly flexible filling technologies with maximum yield, fast product and packaging changeovers, shorter production and delivery times, and digital technologies are the hot topics in the industry. And for each of these, we present innovative answers,” says Dr Andreas Mattern, director of Global Product Management Pharma at Syntegon Technology.

SVP Essential – new basic version with short delivery times

Under the name SVP Essential, Syntegon has launched a new, cost-efficient version of its proven Pharmatec SVP process systems. Thanks to its modular design, customers receive a fully automated, ready-to-use solution to produce small-volume liquid parenterals. Syntegon has developed a series of functional modules that can be assembled in a modular system. This reduces the engineering effort and ultimately the delivery time – to just six months. The compact system is supplied as a ‘package unit’ with a technology skid in the cleanroom, enabling customers to install it independently easily. The Syntegon experts merely carry out the commissioning on site.

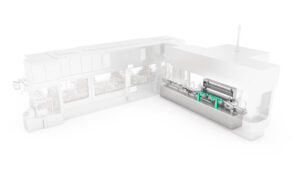

Modular small batches – Versynta Flexible Filling Platform

Syntegon bundles its small and micro-batches solutions in the new Versynta portfolio. The modular Versynta Flexible Filling Platform (FFP) for aseptic and highly potent liquid pharmaceuticals is individually configurable and available with an integratable isolator. It achieves high product yields at low outputs of up to 3,600 containers an hour, partly thanks to 100% in-process control. The machine can be easily converted to a wide range of containers and different filling systems. The pharma handling unit ensures safe and gentle transport by transferring the containers from one station to the next without glass-to-glass contact.

New, patented loading system for freeze dryers

With the new, patented loading system for freeze dryers, the Syntegon product brand SBM (Schoeller Bleckmann Medizintechnik) achieves considerable space savings and maximum process reliability. Thanks to the new front pusher design and its innovative drive, movement is no longer accomplished by a hydraulically operated pusher arm but via the mechanical servo drive of the loading unit. The entire system can be installed within the isolator dimensions while the drive unit is placed outside the product handling area. This innovation saves a lot of space in the fill-finish area and avoids possible contamination. Thanks to improved accessibility, maintenance can be done quickly and without integrity loss in the isolator.

GKF 60 capsule filling – dosing flexibility with a small footprint

The GKF 60 sets new standards in capsule filling for laboratories. The mobile unit facilitates the development of new formulations with various dosing systems – flexibly and at different OEB levels. Scale-up to production is also easily accomplished. With only six stations and three filling stations integrated in parallel, the machine is highly compact and flexible. Even the smallest quantities from 0.1-milligram filling weight can be filled without product loss on the newly developed piezo station. Depending on the version chosen (standard, containment, or combi), the new GKF 60 is suitable for both simple and highly potent formulations from OEB3 to OEB5.

Sepion Coater – experience meets innovation

The Sepion coater series from the Hüttlin product brand features closed material handling and high spray rates at very low relative standard deviation (RSD). The drum can be filled with flexible batch sizes between 10 and 100% of the working volume. The optimized drum geometry with its sophisticated spraying system offers better guidance of the process air and shorter process times with high yields.

In addition, the spray arm can be automatically adjusted for all filling heights. As a result, the new Sepion coater and its containment options ensure an optimum and reliable coating process currently being implemented in the first greenfield projects in Europe and Asia.

MIRA – from preventive to predictive maintenance

With MIRA (Machine Intelligence Reporting & Analytics), Syntegon is taking the next step in digital services. The modular software solution developed by Syntegon for the intelligent monitoring of process-critical components makes downtimes foreseeable and ensures trouble-free production operations. For example, anomalies in fans can be detected by temperature and vibration analyses up to six weeks before a potentially costly failure. As a stand-alone predictive maintenance system, MIRA operates in parallel with ongoing operations and does not interfere with machine controls.