The Fraunhofer Institute for Photonic Microsystems IPMS in Dresden has developed robust, reliable, and versatile ultrasonic sensors for many years. Due to their small size, the so-called MUTs, Micromachined Ultrasonic Transducers, enable energy-saving, multifunctional, environmentally friendly, and extremely compact sensor systems. At the digital trade fair Sensor+Test, the world’s leading forum for sensor, measurement, and testing technology, free of charge for visitors, the institute will present its latest developments to the public from May 4 – 6, 2021.

Examine embryos or tissue in medicine

© Fraunhofer IPMS

Nowadays, ultrasonic sensors are fully integrated into everyday life. They support the driver as parking assistance in automobiles, ensure safety when humans and robots work together, secure filling levels and material flow in the beverage and food industry, or serve as imaging methods to examine embryos or organic tissue in medicine. This versatility is made possible by propagating and detecting high-frequency sound pulses that are inaudible to humans. These ensure non-contact, reliable, and accurate detection of objects for a wide variety of materials regardless of aggregate state, shape, and color under almost any circumstances and in virtually any environment.

© Fraunhofer IPMS

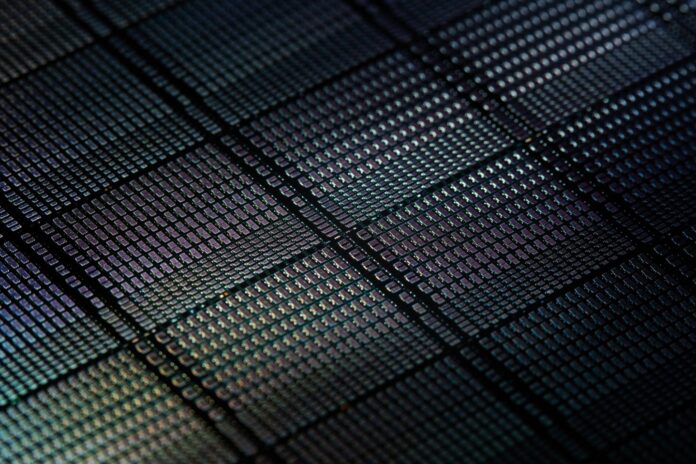

The micromachined ultrasonic transducers (MUT) developed by Fraunhofer IPMS are based on micro-electro-mechanical systems (MEMS). They are critical to the miniaturization of components and devices, without which no high-growth technical sector could survive. “Our miniaturized capacitive micromachined ultrasonic transducers (CMUT) benefit from reliable manufacturing processes in CMOS technology. This enables cost-effective and RoHS-compliant production in high volumes. This is not the case with classic piezoelectric ultrasonic sensors, which are manufactured in a complex precision mechanical process and often contain lead,” explains Dr Sandro Koch, a scientist at Fraunhofer IPMS.

The sensors can be manufactured for a wide range of ultrasonic frequencies to make application-specific ranges and resolutions possible. Sensor solutions can be manufactured in single-channel structures as well as in any two-dimensional array structures. The latter enables, for example, the application of imaging methods for environmental monitoring and are thus pioneering in safe human-robot collaboration.

Evaluation kit

To provide interested parties with a quick introduction to the innovative sensor technologies of Fraunhofer IPMS, the institute offers an evaluation kit. It consists of either one or two CMUT sensor modules, adapted control electronics, and software as a web application that controls the ultrasonic sensor via plug-and-play. The system can send or receive ultrasonic signals with high sensitivity and resolution in the specific working range. The system transmits the data to the web application via Ethernet or Wifi, enabling simultaneous visualization. Users can thus convince themselves of the technical advantages of Fraunhofer IPMS’ CMUT technology with little effort and evaluate this sensor technology for various application scenarios – such as close-range monitoring, acoustic spectroscopy, flow measurement – in which there is a need for miniaturization with simultaneously increased sensitivity.

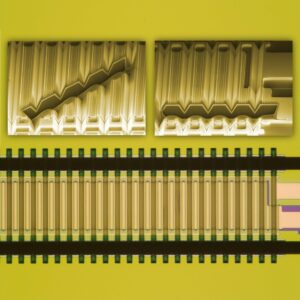

One of the latest developments of Fraunhofer IPMS is the Nanoscopic Electrostatic Drive (NED) MEMS ultrasonic transducer. This technology makes it possible to dispense with the membrane used in conventional ultrasound transducers. Instead, microscopic bending beams are used, which are set in vibration by a signal. These bending beams are arranged in sound chambers to generate sound. Sound exits the sound chambers through inlet and outlet slits. The advantages of this system are very low power requirements and RoHS compatibility, and a high number of degrees of freedom in design.

At Sensor+Test’s accompanying conference, Sensor Measurement and Science International (SMSI), Jorge Mario Monsalve Guaracao, a scientist at Fraunhofer IPMS, will present a micromechanical ultrasonic transducer (MUT), which is used, for example, in the field of gesture recognition.