In September, Bobst organized a webinar to showcase the recently launched Accucheck inline inspection system on its folder-gluers. The new version of the Accucheck system is part of the Bobst Connect open architecture cloud-based platform delivering solutions for pre-press, production, process optimization, maintenance, and market access. The Bobst virtual demonstrations on technical topics have been regular in the past months – they are brief and to the point.

On the new Accucheck, the inspection parameters for diecut cartons being folded and glued through the machine at high speed can be set according to various criteria, covering customer’s quality needs. The system also inspects varnished, metalized, and embossed blanks for defects. It has many other options, such as PDF proofing and providing inspection reports. Its smart text identification feature using machine learning was a world premiere shown to the webinar’s audience.

“Bespoke inspection is now possible with this versatile device where all the inspection modes can be used on the same line. It is a complete quality control system,” said Benjamin Carron, technical product marketing manager at Bobst.

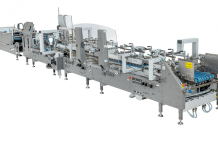

Bobst introduced a fully integrated inline quality control system on a folder-gluer back in 2011 with the first generation Accucheck, providing a seamless progression, with no additional quality control steps required in the process. This solution inspects carton blanks for defects as they enter the Bobst folder-gluer.

The new version of Accucheck is compatible with the latest generation of Masterfold 75 / 110 or Expertfold 50 / 80 / 110 folder gluers. It checks carton blanks for defects and guarantees quality consistency at speeds up to 500 meters a minute, or 140,000 boxes an hour. That makes it the fastest inline quality control machine and allows it to run at full speed with Accubraille. Accubraille gives carton manufacturers the ability to emboss Braille on all four carton panels and even across the running direction.

Venugopal Menon of Bobst India says, “The speed boost to 500 meters or 140,000 boxes an hour is a huge boost in productivity. However, when checking for defects on cartons such as cosmetic cartons with metalized board or foil stamping, the speed is only 150 meters a minute.” Menon adds that only the new Accucheck will be available, and the earlier model discontinued.

Other new features include smart text identification, which is driven by the machine learning algorithm, and a reporting system that can be adapted to client validation targets and is available through a web browser. Accucheck is also equipped with a dust removal device, which removes over 90% of dust particles to avoid unnecessary default detection.

The new Accucheck is equipped with the HMI Sphere, providing several operating modes for customized settings. Inspection parameters can be saved and recalled, with repeat orders set within seconds. Access rights can be varied and specified for individual users.

“The new Accucheck is twice as fast as the first generation. It provides major innovations for value-added boxes with inspection of varnished, metalized, and embossed surfaces. The changeover time is less than two minutes,” said Claude Tomà, Bobst’s product support manager.

During the webinar, Bobst customers talked about their experience with the Accucheck. Frederico Baccolini of Renografica said that his company has been using the first generation of Accucheck. A few years ago, they were on the lookout for an inspection system but did not find anything that met their requirements. That is when they went for the Accucheck first generation.

“Since then, we have been very impressed with the system and are waiting for the new version of the Accucheck,” Baccolini said. Bologna-based Renografica produces quality cartons for the healthcare sector.

Two live jobs demonstrated

During the webinar, Bobst performed quality checks on two cartons that were being simultaneously folded and glued to demonstrate the capabilities of the new Accucheck. One was new, and the other was a repeat order.

The new carton demonstrated being checked on the folder-gluer was a straight-line pharmaceutical carton using 255 gsm paperboard in the 160 x 156 mm format. The pharma carton printed and decorated with five colors and varnish required a thorough check of all small text, among other parameters.

The second job, which was a repeat order, was a value-added cosmetics straight-line carton on 255 gsm paperboard in a 200 x 267 mm format. The cartons printed and decorated in five colors and two varnishes plus hot foil stamping and embossing are particularly challenging and require moderation of the system speed and throughput.