Sabic, a global leader in the chemical industry, is making a significant contribution to the battle against Covid-19 through increased production within its Lexan polycarbonate portfolio. The focus of the production increase has been on innovative polycarbonate sheets and films for a wide variety of high-performance products to help improving sanitation control and preventing infections.

Sabic’s efforts in combatting Covid-19 are boosted by the company having production facilities across Europe, Asia, and North and South America. This provides the company’s functional forms business with the ability to manufacture and swiftly distribute its sheet and film products across every region around the world.

Sabic and its predecessors have a long history as an innovator in polycarbonate technology, having invented polycarbonate resin in 1953, and initiated production of high-performance sheets and films in 1968. Since then, Sabic excels in polycarbonate development with a portfolio of over 350 material grades. Sabic’s functional forms business spearheads materials innovation, enabling applications in industries where there is a need for safety, high optical quality, durability, anti-bacterial properties, and flame, chemical, and impact resistance products.

Lexan protective sheets and films have applications across an extensive range of sectors that are experiencing particular hygiene and social distancing challenges during the pandemic. These include hospitals and medical clinics, care homes, dental practices, schools and kindergartens, retail and hospitality outlets, sports centers, reception areas, and mass transportation, among many others.

“There is an urgent and ongoing need around the world for protective equipment, not only to fight against this current pandemic but also to improve safety and hygiene standards in the future,” said Sandeep Dhawan, Global business director Functional Forms, Sabic. “As a company that excels in ground-breaking materials, we are driven by the ambition to innovate and are committed to providing the latest technology and expertise to prevent the spread of Covid-19 and help mitigate further infection.”

Market takes action against pandemic with Lexan film and sheet solutions

As testament to its global reach, Sabic has supplied innovative polycarbonate sheet and film solutions to some of the world’s organizations for some of the most demanding applications aimed at providing increased protection against Covid-19. Examples include:

Brillant BusGlas, Germany

Helping bus operators cope with distancing regulations in the combat of Covid-19, Brillant BusGlas is offering transparent partition panels for separating bus drivers from passengers in public transportation. The ECE-R43 certified and TÜV approved panels are made from virtually unbreakable, coated 8-millimeter Margard MR5E sheet and available in kits for installation on-site and/or by Brillant’s retrofit service.

“Thanks to the freedom of design and ease of conversion of Sabic’s polycarbonate sheet products, we can customize and supply these partition panels for virtually any public bus brand. The rigidity, outstanding impact strength, double-sided abrasion-resistant coating, and long-term transparency of the material make them an ideal solution providing permanent professional driver protection as well as compliance with current anti-pandemic contact restrictions.”

Image Labels, India

Image Labels supplies face shields to government bodies, police departments, hospital groups, and leading OEMs such as Schneider, as well as partitions for taxis and other modes of transportation.

“Through our association with Sabic, we are now into our 25th year of successfully supplying leading polycarbonate solutions for a wide range of applications,” said Sujan Nailady, managing director, Image Labels. “We are particularly appreciative of the support Sabic has provided in helping to overcome some of the challenges posed by the Covid-19 pandemic.”

Krüger Aviation GmbH, Germany

For the aviation industry to recover from the economic impact of the pandemic, airlines must instill confidence in passengers using their aircraft without the costly need to implement an empty seat policy. Krüger Aviation has taken up the challenge by developing seat dividers, made from Sabic’s Lexan F2000A polycarbonate sheet, which provide passengers with a high level of protection from any aerosols produced by neighbors. The seat divider, which is attached to the middle seat in rows with three seats, is constructed for easy mounting without need of any modification of the seat itself, with a full aircraft being equipped within a few hours.

“While facemasks may be still required, seat dividers will establish an additional layer of protection and significantly reduce risk of infection,” said Florian Ehinger, head of Customer Service. “We believe this will be a highly cost-effective way to help restore passenger trust in airline travel.”

Focaccia Group, Italy

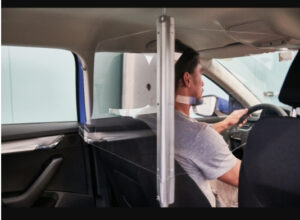

Using Sabic’s Lexan Margard MR5E polycarbonate sheet, Focaccia has designed and manufactured the first “L”-shaped anti-Covid partition, which can be installed in vehicles to separate the driver from passengers. Called the “Elle Corona Stopper,” the partition does not obstruct the driver and does not interfere with airbags, mirror view, seat belts, or safety systems. It can be installed in minutes, removed without damaging the car interior, and can be completely disinfected.

“Sabic’s Lexan sheet has enabled us to deliver the desired characteristics of resilience and creativity in manufacturing for which we are known,” said Riccardo Focaccia, general manager, Focaccia Group. “Even in challenging times, our ideas never stop, and a flexible polycarbonate solution enables some of our other creative ideas come to life.”

Sabic products to enable better protection against viruses

Sabic’s next-generation Lexan sheet and film solutions have all been developed to bring chemistry that matters to the marketplace. The journey of innovation will be highlighted with technology that supports anti-bacterial performance to assist in the fight against Covid-19 across its portfolio. Sabic Lexan polycarbonate solutions are available through an extensive network of localized distribution centers globally.