The product mix for cartons has changed in the past two years with an increase in litho-laminated cartons. Litho-laminated cartons are generally an offset printed packaging board that is pasted on an E- or F-flute (micro-flute) corrugated sheet and then die-cut and creased on a diecutter and put through a folder gluer for making the boxes. Since the majority of monocarton converters in the country operate within the B1 format (102-106 cm or 40-inches), for slightly larger white goods consumer products, this could also mean that the final carton is made of two pieces.

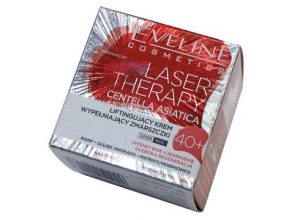

Consumer product manufacturers are asking for more litho-laminated cartons than before. Moreover, they want the same shelf impact for a coffee-maker or a pressure cooker carton as they see on the luxury cartons for personal care and cosmetics. The glittering and haptic effects of metallics and foils, the texture of varnishes, and even embossing effects are now considered desirable for more or all consumer products.

The internal fitments of the packaging have to be provided for the product to withstand the logistics of warehousing logistics and eCommerce last-mile delivery. In addition, machine-readable product identification is needed for pick and place in the warehouse and inventory control. In the case of some product cartons, pilfer proofing may also be required – since the value lost in case of theft is not just of the product but also of the excise taxes paid.

There is also the shift to paper for food service products and packaging to avoid the use of plastic and to be compliant with the ban on the use of select single-use plastic items. While many converters are purchasing coated boards with moisture barriers, others are developing their own products using offline pasting and coating machines. For many other consumer products, the combination of paperboard and plastic is likely to shift to a paperboard with specially shaped board and paper fitments inside.

Thus the old formula of one multicolor press, two autoplaten die-cutters, and one folder has become more complex. The number of die-cutters and folders is increasing at a slightly higher rate than the earlier ratio because litho-laminated packaging takes much more space not only as work in progress but also on the feeder board of a die-cutter or folder-gluer. The change has also come because of the affordability of higher quality Asian and Indian-made die-cutters and folder-gluers with a high level of local service commitment.

In the modern carton-making plant, there is an increasing proliferation of several finishing equipment, earlier considered luxuries. Corrugated pasting machines or automatic lamination have become an essential requirement. Offline coaters in addition to the inline coaters are also useful for special coatings at times.

A number of hot foil stamping and embossing machines, and blanking machines, are being added to the shop floors of even the mid-level carton producers. Single-color gravure presses for adding gold and silver are being imported by even newcomers to the carton business. Paper and board pasting machines are also essential. In the case of suppliers to the food service industry, tray forming equipment is also needed.

The variety of cartons required by what was earlier a simple monocarton (solid board or folding box board) printer and converter has grown and become more complex. The complexity will continue to increase especially when track and trace elements such as RFID antennae and various types of holograms are added or embedded in the packaging.

It reminds one of the complexities of a modern bookbinding facility where there are a large number of special machines for round case making, cornering, gilding, embossing, perforation, and other pieces of decoration that are meant only for specific products. At one time these were considered frills and cost centers.

Perhaps with the currently growing demand scenario for packaging, this ancillary equipment will become essential. Hopefully, as the value add machines become more capable and automated, they will point the way to more interesting, active, intelligent packaging. Even new shapes and creative cartons with more wow factor.