Toyochem, the polymers and coatings subsidiary of Japan’s Toyo Ink Group, has launched a new line of Bisphenol A non-intent (BPA-NI) internal coatings for metal cans.

Based on acrylic emulsion and polyester resins, the new BPA-NI internal sprays and coil coatings for stay-on tab (SOT) ends are specially formulated to achieve the required performance results while addressing BPA-related health and food safety concerns from regulators and consumers alike. Moreover, Toyochem will be marketing its BPA-NI solutions under the new brand name Lionova, as the company seeks to expand its position in markets overseas.

Traditionally, epoxy resins were used to line the interiors of metal food and beverage metal cans. Since epoxy resins are made from Bisphenol A, a potentially endocrine-disrupting substance, epoxy coatings contain small BPA traces, causing health issues. As a result, demand for BPA-NI coatings is gathering momentum as government agencies worldwide start to regulate BPA more strictly and even ban its use in food packaging altogether. This trend has resulted in a shift toward BPA-free packaging in end-use industries.

To meet this rise in demand, Toyochem researchers in Japan applied its polymer design technology to formulate can coatings that do not contain BPA and have very low free monomer content. Designed with human and environmental health in mind, Lionova coating compositions are based on FDA (21 CFR175.300). In evaluation testing, styrene concentrations were below the detection limit of 0.001 µg/L.

Lionova systems offer excellent bendability, durability, suitability with a wide range of container types, and retort resistance levels needed to meet the performance requirements of today’s canmakers.

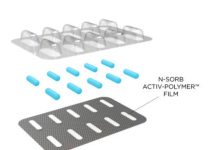

The Lionova Lineup for metal cans

The acrylic-based LIONOVA-500 for can end coating is a soap-free emulsion suitable for applications that require high hygiene or high-temperature sterilization. They demonstrate exceptional feathering resistance during the shaping process relative to BPA-epoxy coatings, achieving values of around 80µm at a dry film weight of 110 mg/dm2.

The high-performance polyester-based LIONOVA-600 formulation comprises optimal functional groups that help form an optimum cross-linking structure, resulting in exceptional formability and barrier properties based on the polyester’s molecular weight glass transition point. These coatings are highly flexible and durable with 3T-Bend ERV of 0.1 mA at 110 mg/dm2.

Rounding out the Lionova BPA-NI lineup is the LIONOVA-100 acrylic spray lacquer for DI cans, demonstrating excellent spray coverage at high speeds and good flavor properties. Toyochem offers the LIONOVA-300 acrylic internal spray features superior bendability and spray coverage reliability for screw processing applications for the metal cans make interiors.