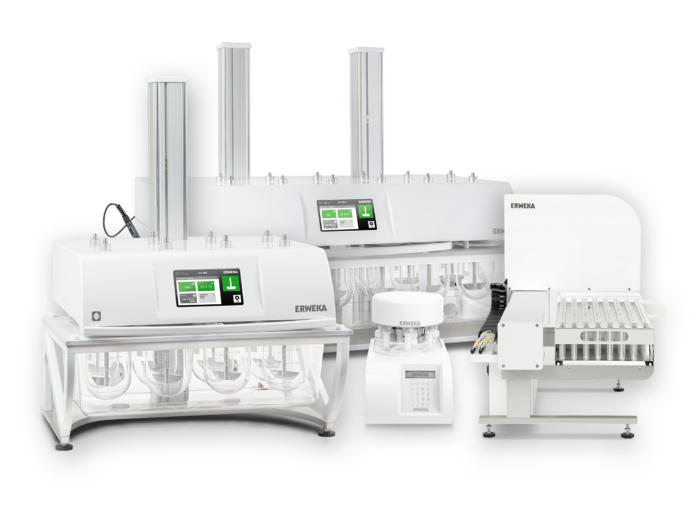

Erweka, a global name in pharmaceutical testing equipment, has highlighted its digital dissolution offline system for the DT 950 and DT 9510 series, an integrated offline sampling solution that automates dissolution testing, strengthens data integrity, and maintains pharmacopoeia compliance on existing DT platforms. The system combines digital control, guided workflows and modular hardware to enable powerful, automated dissolution testing with automated sampling.

The digital dissolution offline system delivers fully automated, precisely timed sampling and storage in vials or tubes for separate analysis, removing the need for highly skilled manual pipetting and achieving a level of timing precision that is not realistically attainable by hand.

This guided setup on a 7-inch touch display walks users through configuration and sampling parameters, making operation intuitive and supporting standardized workflows across instruments and operators. This combination of automation and guidance helps laboratories shorten setup times while improving reproducibility from run to run.

21 CFR Part 11 compliance and regulatory data integrity are at the core of the system’s built-in Audit Trail, providing an FDA-aligned framework for secure electronic records and user actions directly on the instrument. The platform supports the same pharmacopoeia methods as the DT 950 and DT 9510 series, enabling a broad range of standardized dissolution tests to be run on a single ecosystem. Integrated user management with configurable roles allows organizations to define clear responsibilities for administrators, operators, and service personnel so only authorized users can adjust critical settings.

By delivering 21 CFR Part 11 compliant control without the need for an external PC and separate software layer, the system simplifies qualification, reduces infrastructure overhead, and keeps compliance management close to the instrument. Centralized handling of the complete digital offline system at the instrument helps maintain compliant operation without complex manual configuration, reinforcing confidence in every test.

As a stand-alone digital dissolution offline system, the solution provides a straightforward entry point into advanced dissolution automation. Laboratories can adopt the offline system for existing DT 950 and DT 9510 instruments and expand over time as testing volumes and method portfolios grow. Speed and volume ranges are designed to support typical dissolution requirements on one platform, allowing teams to handle different media volumes and test designs without changing hardware. Multiple connectivity options make it easier to fit the system into existing IT environments and to integrate with laboratory information management systems and networked data workflows.

The DT 95x series offers configurations with six, seven, or eight test stations in two rows, allowing laboratories to select the capacity that fits their current workload while maintaining a compact footprint on the bench. This gives smaller and mid-throughput QC labs an efficient path to automation without over-investing in capacity they do not yet need. For higher-capacity environments, the DT 951x series extends the concept to 12, 13, or 14 test stations in two rows, giving busy quality control laboratories a way to perform mid-to-high throughput dissolution testing and side-by-side batch or formulation comparisons on a consistent platform. Having both series within the same digital ecosystem allows organizations to standardize training and workflows while matching capacity to each site’s needs

Across both series, the digital dissolution offline system is engineered for dependable performance in standard laboratory environments. Operating and storage ranges are selected to support stable dissolution conditions while simplifying logistics and transfer between locations, helping laboratories maintain consistent performance without specialized infrastructure. Optional temperature sensors in each vessel document actual medium temperatures during every test, supporting robust methods and parallel batch comparisons. Flexible sampling positions, including high-head, low-head, and a dedicated cleaning mode, give users more control over sampling geometry and make it easier to clean and maintain the system between runs.

The system, DT 950 and DT 9510 dissolution testers form a cohesive ecosystem for automated, compliant, and scalable dissolution testing. By combining guided digital control with modular offline hardware and built-in data-integrity features, Erweka enables laboratories to streamline dissolution workflows, reduce operator dependency, and support evolving testing and compliance requirements on a single, extensible platform.