Sea Vision, a supplier of machine vision systems for the pharmaceuticals industry, is presenting some of its technological solutions at Pack Expo Las Vegas, a leading packaging and processing fair to be held from 11 to 13 September at the Las Vegas Convention Center in the US.

At booth number 6901, Sea Vision will present solutions such as the inspection of glass vials, syringes and carpules; serialization and aggregation, to quickly comply with the fast-approaching DSCSA deadlines; and the automation of line clearance and 4.0 suite processes.

Vision inspection controls on vials and syringes

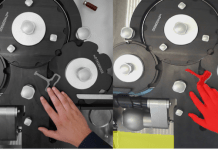

The initial area of focus will be the inspection of glass vials, syringes and carpules. Sea Vision will have a demo station equipped with a hardware kit and a software program (usually installed on the vial or syringe filling and capping machines, as well as on syringe assembly machines) to show the real-time detection of – vial crimping defects; flip-off caps and their correct color; stoppers and their correct position; caps and their position; syringe assembly defects; labels and their correct application.

These inspection solutions have been designed to meet the quality control and product integrity needs, to identify and report the presence of defective products to the packaging machinery in order to prevent them from being distributed, the company said.

Another crucial aspect is serialization and aggregation, and with the FDA’s deadline for compliance with the Drug Supply Chain Security Act (DSCSA) rapidly approaching, it is important for pharmaceutical manufacturers to find a way to comply with these regulations.

Sea Vision will showcase TrackPCA, a compact workstation designed to manage the serialization of cartons and multi-level aggregation on cases and pallets all at once, allowing for quick and efficient compliance.

The skills and experience of Sea Vision in cutting-edge Track & Trace software architecture allow manufacturers to be ready in time for the DSCSA’s final deadline of 27 November 2023. In fact, the station manages the printing and checking of the variable data and codes to serialise cartons; the presence of a built-in label printer allows parent-child aggregation to be performed up to the pallet level, and partial cases and pallets can also be managed.

yudoo at Packexpo

Then there is yudoo, a platform that links automation devices, machines, IT and control systems together in order to manage the entire pharmaceutical production process and, at the same time, collect and analyze data to turn manufacturing insights and traceability insights into action and drive results in terms of OEE improvement.

The full version of yudoo includes features for managing production lines, integrating existing Track & Trace architecture for serialization management, real-time OEE performance analysis, and evolved KPI’s based on Business Intelligence tools.

At Pack Expo Las Vegas, visitors will have the opportunity to meet Sea Vision product experts to know more about the AI-powered automated line clearance solution “a-eye clearance”.