The Marchesini Group returns to the Jacob K Javits Center in New York on April 28-30 for the 41st edition of Interphex 2020, the premier pharmaceutical, biotechnology, and device development and manufacturing event in the US.

Marchesini Group USA – the American subsidiary of the Marchesini Group – is expecting high attendance at Booth no 3125, where three stand-alone machines will be on show – the Marchesini BL-A420 CW labeler, the CMP PHAR.MA SV inspection machine and the Axomatic Axo 800 tube filling and closing machine.

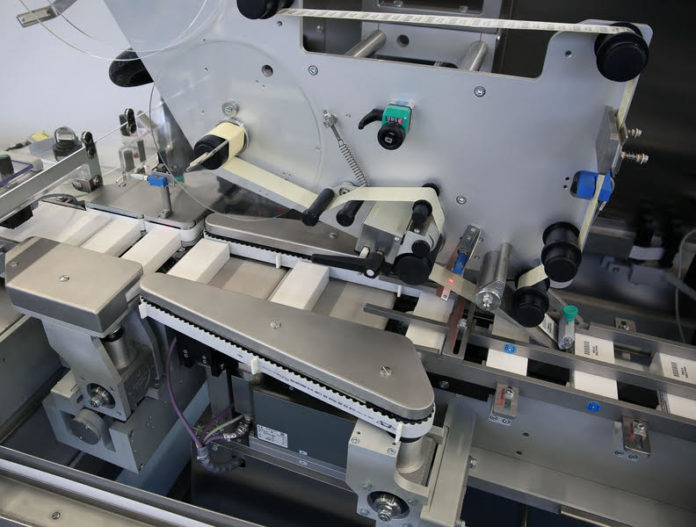

BL-A420 CW labeler is much more compact than the classic solution (carton labeler or print or inspect the machine and separate stand-alone checkweigher) and much more compact than the versions offered by the competitors.

According to the press release, the cartons are fed and accumulated in-line on the inlet belt to ensure a continuous flow of products, even at high speeds. A patented timing device positions and set the cartons apart correctly on the toothed belts with an adjustable opening, which also prevents slipping.

The function of the timing device is to set the cartons at the correct distance apart; its special feature is that it is synchronized with the speed of the whole conveyance system, and there is no need for any size change-over adjustments.

A load cell is fully integrated into the stepper conveyance system and is able to check the weight of each carton. By integrating the load cell into the toothed belt system of the BL-A420 CW, the machine is able to verify the position of the cartons at all times. If the weight is correct, the product will then proceed to the next step (printing, inspection or serialization, and sealing). If the weight is not correct, the subsequent processes are skipped and the carton is rejected, according to the “Fail-Safe” operating logic.

The first operation to be performed after the cartons have been checkweighed is the application of the vignette label on the upper panel of the cartons. After the vignette has been applied, the unique 2D code (Datamatrix) and the corresponding human-readable data are printed on the side flaps and sometimes on the upper panel. The unique code identifies and makes it possible to track each carton.

A camera then verifies both the codes and the readable data. After print inspection, two self-adhesive Tamper Evident seals are then applied on the corner closing points of the cartons.

The model showcased is equipped with a new operator interface called “Easy Door”. This version has several improvements from both a functional and aesthetic point of view. The new software makes the operating system more powerful and faster. The wider screen is more ergonomic, and the touch screen is easier to use, similar to that of a mobile phone.

The high level of flexibility of the BL-A420 CW means that all types of printing and vision systems available can be installed on it, which can be customized according to all the current standards worldwide. This special feature makes the BL-A420 CW the most suitable and complete machine for tracking, serializing, and labeling cartons, giving a unique identity to all the pharmaceutical products packaged. The machine can process up to 400 cartons in a minute.

Alongside the BL-A420, CW will be the SV model designed by CMP PHAR.MA The SV is a semi-automatic machine for the inspection of liquid, lyophilized or powder products in ampoules, vials, and cartridges or pre-filled syringes. It is equipped with brushless motors for fast rotation (before inspection) and slow rotation (during inspection) to guarantee complete and efficient product control. The machine can handle up to 100 pieces in a minute.

Following the CMP acquisition in December 2018, the Marchesini Group can now offer complete lines for producing and monitoring the whole pharmaceutical packaging process, from start to finish, including the Group’s partner, SEA Vision, which also participated in the CMP transaction.

Finally, on display will be the Axomatic Axo 800 tube filling and closing machine for plastic, laminated, or aluminium tubes. Axo 800 is equipped with a control touch and screen panel with all the main functions, an automatic filling with mechanical dosing system with dosage range between 3 and 250 ml and it offers the possibility to produce a shaped sealing system according to customer drawings such as round edges, curved seals, and wave seals. The machine works with an output of 60 pieces in a minute.