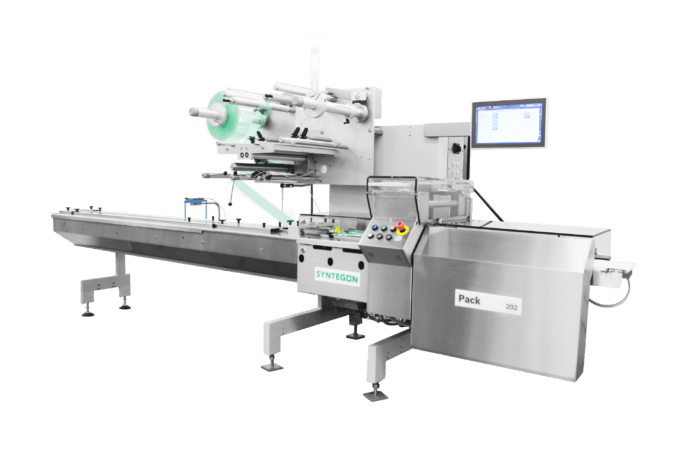

Syntegon Technology has launched the next generation of flow wrappers – Pack 202, a fully automated horizontal flow wrapping machine suitable for low to medium speeds.

The successor of the Pack 201, the flow wrapper is suitable for bars, bakery products, cookies, crackers, and non-food applications. According to Syntegon, with the Pack 202, manufacturers benefit from several technological advances that were first introduced on the new Pack 403 last year, including an easily removable discharge belt, upgrades to the cross-seal and fin seal units, and a highly intuitive, user-centered design.

“Our new flow wrapper for small to mid-sized manufacturers certainly packs a punch. We were able to integrate some of the features of our Pack 403 for medium to high speed applications into the new Pack 202. The machine is easy to operate, clean and maintain, which reduces downtime and maximizes overall equipment effectiveness,” Kelly Meer, product manager at Syntegon in New Richmond, Wisconsin, USA, states.

Technological upgrades for improved seal quality

Suitable for multi-product applications, Pack 202 can wrap individual or grouped products including bakery goods, bars, fresh and frozen products, confectionery, snacks, medical products, prepared foods, household goods, and much other food and non-food items.

The Pack 202 profits from several cross- and fin-seal improvements that were first introduced on the Pack 403 flow wrapping machine last year. Syntegon highlights that the finwheel modules have been synchronized, and the Pack 202 now features an improved canting mechanism – at the turn of a knob, operators can tilt the fin modules.

The cross-seal unit on Pack 202, according to the company, has also been improved significantly. The standard double-spring kit claims to offer more consistent and stable seals, while the adjustment resolution has been doubled, thus enabling more precise and repeatable crimper adjustments.

User-friendly design for easy handling

User-friendliness and ease of operation are at the heart of the Pack 202’s design, claims Syntegon – just like the Pack 403. Several features on the Pack 403 have been integrated into the Pack 202 to improve the user experience. The machine’s sequentially numbered film rollers will enable film threading for repeatable, consistent changeovers and reduce downtime caused by trial-and-error adjustments. Syntegon’s new machine includes an optional automatic film splicer with laser-etched instructions on the deck plate to facilitate quick and smooth film changes without disturbing the machine.

Syntegon has equipped the Pack 202 with a standard 450-millimeter dual back stand. Depending on brand owners’ needs, a 650-millimeter single back stand is also available. The Pack 202 is equipped with a one-meter-long reject belt. The upper section of the reject belt is easy to remove for quick belt changes and cleaning processes. The detection function on the short discharge belt rejects faulty packages and automatically ejects them using compressed air. For larger and heavier products, a two-meter-long discharge module with reject plow is available as an option.

Syntegon has intensified its efforts to develop intelligent and sustainable technologies. The packaging experts work with material suppliers and brand owners throughout the supply chain to test and adjust the machine run ability of alternative packaging materials.