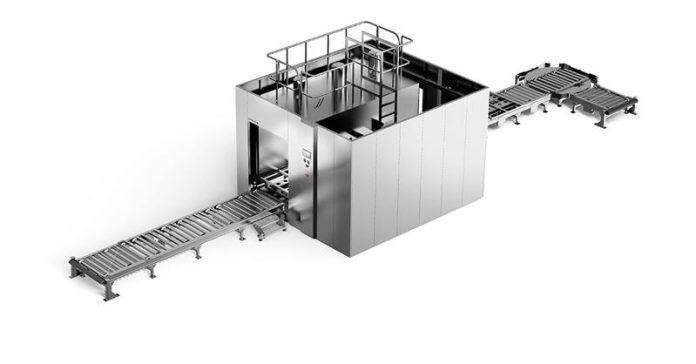

Getinge, a Sweden-based global medical technology company, has introduced a modular and fully automated load handling solution for seamless integration with the company’s GEV terminal sterilizers. In addition to the safety benefits for operators, the new Getinge Roller Conveyor System (GRCS) optimizes throughput performance in pharmaceutical production.

A terminal sterilization cycle includes many safety considerations, such as repetitive strain when lifting, pushing or pulling heavy loads, or accidental damage caused by forklifts or other machinery when loading the sterilizer chamber.

“A fully automatic system is the best solution for heavy, fragile production batches. Our new roller conveyor helps mitigating factors that could impact the safety of operators and the integrity of the sterilizer,” says Magnus Nilsson, Product Line manager for automation at Getinge Life Science.

The automated system, which can handle up to 2,000 kilo per pallet/section, loads and unloads batches of products into and out of Getinge GEV steam/air mixture sterilizers, which are used for pharmaceutical products that must be dry and ready for further handling immediately after the cooling phase.

“The conveyor system’s seamless integration with our GEV sterilizers is maximizing throughput while ensuring repeatable and validated process control. Automated reporting delivers full traceability of the loading racks,” Magnus explains.

The new system is based on a motorized roller carriageway, which makes the placing of batches onto the GRCS independent of feeding them into the sterilizer. Once the sterilization cycle is complete, a carriageway at the opposite end of the sterilizer can support the unloading process.

The modular design makes the Getinge Roller Conveyor System suitable for all production environments.

“The flexibility allows for carriageways of bespoke length, and restricted spaces can be accommodated with turntables for 90o degree changes of the carriageway direction. Each GRCS carriageway can also be configured to connect with existing upstream and downstream conveyor systems if this is required,” Magnus concludes.