March 9, 2021, Tokyo, Japan—Toyo Ink SC Holdings Co.Ltd., the parent company of the specialty chemicals manufacturing conglomerate Toyo Ink Group, and ITOCHU Corporation, a leading global trading house, have entered into a cooperative agreement to establish a plastic recycling scheme for the recovery and reuse of multilayer film packaging materials.

Specifically, using their respective technologies and vast business networks, the two firms will develop the materials technology needed to create real circularity of multilayer flexible packaging by making currently unrecyclable multilayer plastic packaging into a recyclable material by 2022. The collective goal is to boost the plastic material recycling rate to more than 40% in Japan and abroad. At present, the recycling rate in Japan is about 27%.

Recently, the waste problem of single-use plastics has been attracting global attention. In Japan, while about 16% of plastic waste is burnt, buried, or otherwise processed without being reused, about 56% rely on incineration methods, such as thermal recycling and heat reclaiming. Currently, large amounts of plastic are not recycled.

Unique Deinking & Delamination Technology

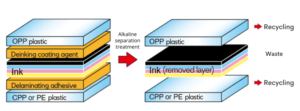

To address the plastic waste issue in 2019, Toyo Ink, incorporating with a leading environmental solutions provider, developed an innovative plastic recovery technology for multilayered flexible packaging, where a deinking coating agent and a delaminating adhesive are applied to the plastic film surrounding the ink layers (see figure 1). After use, the packaging waste is subjected to an alkaline treatment in which the coating agent, adhesive, and interlaying ink layers are cleanly released from the film substrate. This results in the recovery of high-quality plastic material (see figure 2) that can then be reused to create new value products. A pilot plant based on this plastic recovery process is currently being built in Japan and is set to become operational later this year.

Promoting Eco Packaging Design & Technology

Under the agreement, ITOCHU will widely promote environmental solutions to food and daily necessities manufacturers, retailers, and brand owners, by encouraging the development of packaging structures that use this recycling technology and by promoting eco-packaging design. In addition, ITOCHU will acquire exclusive marketing rights in Japan and preferential negotiation rights in Asia and Europe related to major product materials associated with this recycling technology.

“We are delighted to partner with ITOCHU in this ambitious project,” said Shiina Harako, Project Manager, Marketing Division at Toyo Ink Co., Ltd., a company subsidiary. “The ITOCHU Group brings to the table a whole host of major players in the global packaging value chain who shares our vision of creating a recycling-oriented society. Through this partnership, we hope to carve a clear path to realizing a circular economy for post-industrial plastic waste in Japan and elsewhere. This initiative is also a major step in Toyo Ink’s strategic plan to start a post-industrial recycling business in 2022 and post-consumer recycling business in commercial plants by 2025.”

Smart Packaging Solutions Virtual Congress -19 March 2021

The Smart Packaging Solutions for India and South Asia Virtual Congress on 19 March focuses on food and pharma supply chains, brand security, and sustainability. Organized jointly by IPPStar and the AIPIA, the virtual congress’s topics include brand authentication, condition monitoring, and active and intelligent packaging that contributes to the safe delivery of authenticated products leading to safety, security, and customer engagement. Please look at the agenda of the conference here, and for registration, please click here. You can also email Ruchi at conference@ippgroup.in or Umesh at subscription@ippgroup.in. Call us in Noida at 120-4546988 or 4326053 – Umesh at Xtension 30; Ruchi at Xtension 33; Gaurav at Xtension 23; and Mohit at Xtension 25.