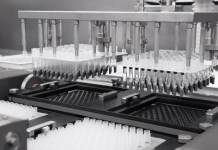

Technology created by a multidisciplinary research group at Bologna University in collaboration with Marchesini Group, enables the production of filtration materials for face masks with greater protection against viruses and bacteria compared to materials currently in use. The researchers are now finalizing the development of the machine, which should be fully operational in the space of a few weeks.

“The prototype enables industrial-scale production of this new type of filtration material based on electrocharged polymer nanofibres”, explains Andrea Zucchelli, a professor with the Department of Industrial Engineering at Bologna University, and one of the project coordinators. “We embarked on a co-design operation in partnership with Marchesini Group, which responded to an appeal we launched in Bologna, and in under two months thanks to vital teamwork, we came up with this machine”.

Once up and running, the prototype, which is housed in the laboratory of the Department of Industrial Engineering (DIN) in Bologna, will produce enough filtration material for around seven thousand masks per day. The first production runs of these materials will be used to produce a prototype batch of FFP3-type masks by Zola Predosa-based company GVS, a leader in the supply of advanced filtration solutions for highly critical applications and a major world producer of personal protection equipment, which has been involved in the project from the outset.

It all began shortly after the start of the coronavirus outbreak – given the huge spike in demand for appropriate personal protection equipment, an interdisciplinary research group at Bologna University set about developing a filtration material that would offer high protection against the risk of contamination from bacteria and viruses. The group was led by professors Andrea Zucchelli of the Department of Industrial Engineering, Maria Letizia Focarete of the “Giacomo Ciamician” Department of Chemistry and Davide Fabiani of the “Guglielmo Marconi” Department of Electrical, Electronic and Information Engineering.

“Only a University environment could nurture and support a project of this kind, designed to rapidly and effectively combine notions from the fields of mechanical engineering, polymer research and electrical engineering to develop an advanced electrospinning technology”, states Zucchelli.

One of a kind, the prototype will be fully operational shortly, as soon as the final set-up activities are completed. The first masks to be produced will be of the FFP3-type, offering ultra-high protection against viruses and bacteria, but the researchers are already working on new ideas to further broaden applications of this new technology.